PRODUCT OVERVIEW

Electric three piece ball valve is a valve (ball) that rotates 90 ° around the axis perpendicular to the channel. It is composed of angular stroke electronic electric actuator and O-type valve structure. It is a rotary type high-performance regulating or on-off valve. It receives the input and output of current signal or voltage signal from industrial automation control (DCS, PLC system) instruments, It can realize the proportional adjustment or two position switch control of the fluid medium in the process pipeline, so as to achieve the automatic control of the flow, pressure, temperature, liquid level and other parameters of the fluid medium. The ball core channel is flat and smooth, it is not easy to deposit the medium, and the pipeline ball passing can be carried out. The utility model has the advantages of simple structure, light weight and good sealing performance, and is especially suitable for occasions requiring low leakage rate.

PRODUCT FEATURES

The electric three piece ball valve has small fluid resistance, which is one of all valves with very small fluid resistance. It can control the operation by using AC220V, AC380V or DC24V power supply voltage and receiving (4-20mA, 0-10mA or 1-5vdc) current signal or voltage signal. It can complete the opening and closing action or adjustment action by rotating the ball 0 ~ 90 ° with the torque output by angular stroke, The electric three piece internal thread ball valve adopts full electronic electric actuator and adopts electromechanical integration structure. It has the functions of internal servo operation, opening signal, position feedback, position indication and manual operation. It has strong function, reliable performance and simple connection. The rotation angle of the ball core (0-90 ° arbitrary angle) can be changed by inputting current signal or voltage signal, Realize proportional adjustment action.

MAIN TECHNICAL PARAMETERS

Technical parameters of electric actuator | Valve body parameters |

Power Supply | AC110��、220��、380V/DC24����、220V | Nominal diameter | DN15-200mm,NPS 1/2"-8" |

Output torque | 50N·M~2000N·M | Nominal pressure | PN1.6-4.0MPa�����、CL150����、JIS10K |

Optional function | Switch type, contact type, opening signal, intelligent type | Valve shaft material | Stainless steel |

Action range | 0~90°±5° | Body material | Carbon steel, 304 / 316 / 316L stainless steel |

Action time | 15S/30S/60S | Sphere material | 304/316/316L stainless steel |

ambient temperature | -30°~60° | Seat Tightness | PTFE����、PPL���、Metal seal |

Manual operation | With handle operation | Temperature | PTFE≤180℃��、PPL≤350℃����、Metal seal≤450℃ |

Limit | Electrical and mechanical double limit | structural style | Three piece, butt welding, socket welding, two piece |

Degree of protection | IP-67(Explosion proof enclosure: Exd Ⅱ BT4 IP67 (optional) | Applicable media | Water, petroleum, acids, viscous fluids, slurry media, etc |

Input signal | 0-10����,1-5VDC/4-20mA(intelligent) | characteristic | Compact structure, small volume and large circulation capacity |

MAIN TECHNICAL PARAMETERS

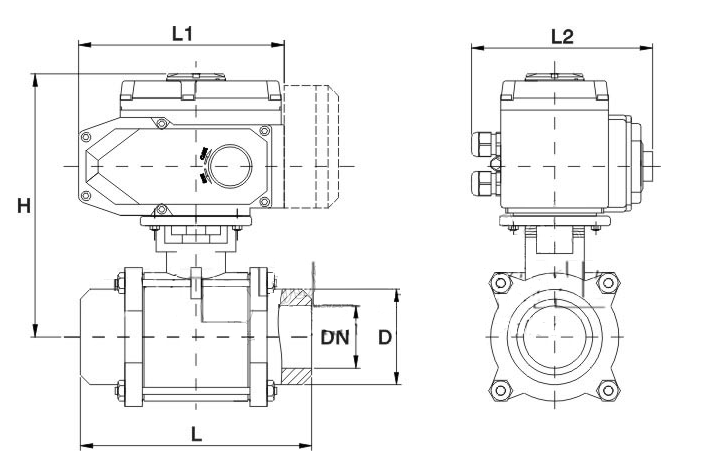

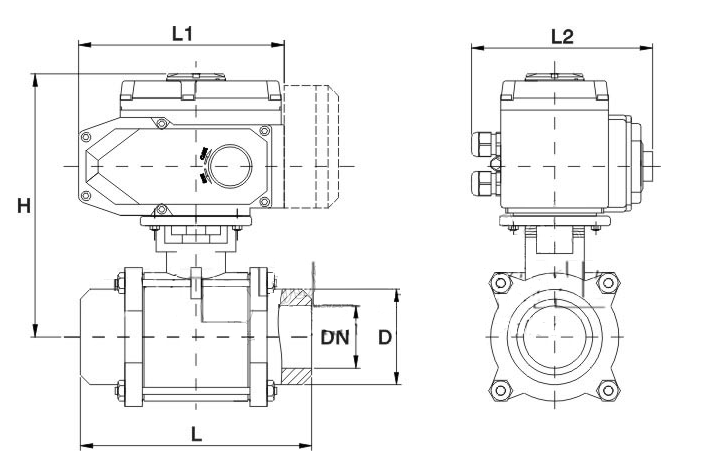

| Nominal pressure | Nominal diameter | L | L1 | H | W | weight(kg) |

| Mpa | mm | in | mm | mm | mm | mm | 1.6 | 2.5 | 4 | CL150 | JIS10K |

1.6

2.5

4.0

CL150

JIS10K | 15 | 1/2 | 130 | 65 | 62 | 100 | 2.5 | 3 | 3.5 | 2.5 | 2.5 |

| 20 | 3/4 | 150 | 75 | 68 | 160 | 3 | 3.5 | 4.5 | 3 | 3.6 |

| 25 | 1 | 160 | 80 | 75 | 160 | 4.8 | 5 | 6 | 5 | 5 |

| 32 | 1-1/4 | 180 | 90 | 85 | 200 | 6.5 | 7 | 8.5 | 7 | 7 |

| 40 | 1-1/2 | 200 | 100 | 95 | 200 | 8.5 | 9 | 10.5 | 9 | 9 |

| 50 | 2 | 230 | 115 | 110 | 250 | 11 | 12 | 14 | 12 | 11 |

| 65 | 2-1/2 | 290 | 145 | 130 | 300 | 15 | 17 | 20 | 16 | 16 |

| 80 | 3 | 310 | 155 | 155 | 400 | 21 | 22 | 32 | 21 | 22 |

| 100 | 4 | 350 | 175 | 180 | 500 | 33 | 36 | 50 | 36 | 36 |

| 125 | 5 | 400 | 200 | 250 | 600 | 65 | 70 | 80 | 68 | 70 |

| 150 | 6 | 480 | 240 | 275 | 800 | 103 | 110 | 120 | 105 | 105 |

| 200 | 8 | 580 | 290 | 325 | 1000 | 152 | 168 | 180 | 160 | 160 |